The full name of cast ceramic is lithium disilicate glass ceramic, also known as cast ceramic full crown. In the mid-1980s, cast porcelain began to be applied in the field of oral restoration, and in recent years, it has attracted much attention due to its excellent aesthetics. It is a newly emerged full crown restoration made of a new type of castable ceramic material, which is superior to metal porcelain teeth in appearance and biological performance. Their biggest difference lies in the inner crown. The inner crown of porcelain teeth is made of porcelain, which is a transparent skeleton without a metal base layer.

Characteristics of Beiyuan Porcelain Casting

·Multiple colors and transparent colors

·High hardness and outstanding toughness

Better durability and biological adaptability

·Similar refractive and optical properties to porcelain veneers

Accurate positioning after pressing

·Outstanding compatibility with various materials

·The optimal hardness for easily adjustable dentures

Product Introduction

The lithium disilicate glass ceramic block used for Beiyuan all ceramic dentures is a lithium silicate glass ceramic produced using die-casting technology. The production process requires the production of ceramic blocks with different levels of transparency and uniformity. These ceramic blocks have a strength of 400 MPa, making them pressure ceramic blocks with strength. These ceramic blocks can be processed in a porcelain casting furnace to produce restorations with matching properties. Aesthetic restorations with tooth color under pressure can be dyed, decorated, and glazed using Beiyuan porcelain powder.

The difference between porcelain casting and porcelain veneers

The biggest difference lies in their inner crowns (porcelain crowns have two layers, with porcelain on the outside and a supporting skeleton on the inside, which is the source of strength for porcelain crowns, known as inner crowns). Porcelain fused to metal inner crowns are made of metals such as nickel chromium, titanium alloys, precious metals, etc., while metals are opaque. Cast porcelain inner crowns are also made of porcelain. White garnet (first generation), lithium based ceramics (second generation), etc. have transparent skeletons.

The production process of porcelain casting

All ceramic teeth are cast using the traditional lost wax casting method, where the metal is replaced with finished ceramic blocks and the inner crown is formed by vacuum high-temperature casting and pressing of lithium disilicate ceramic. The casting process is carried out using a vacuum casting and pressing casting machine. The all ceramic inner crown and outer ceramic powder are chemically bonded, resulting in high strength. The flexural strength of cast porcelain teeth is 420MPA, which is close to that of natural teeth and will not cause too much wear on jaw teeth. This process belongs to handmade production with very high precision and also requires a high level of skill from technicians.

Advantages of Porcelain Casting

Transparent:

--This is a task that porcelain veneers find difficult to accomplish, as the opaque nature of the metal crown requires opaque porcelain to cover the metal base, which affects the transparency of the restoration and results in a noticeable chalky, pale, and false appearance after porcelain veneers cosmetic treatment. Additionally, the presence of a metal base at the neck of the tooth can cause issues; Black line” Affects aesthetics. Porcelain casting solves this beauty problem with a high-strength inner crown that has good transparency and refractive index, allowing the dental neck to achieve a good aesthetic effect.

Gum discoloration:

--Base metals oxidize in the oral cavity to form gray oxides, which scatter and deposit at the edge of the gums, causing them to turn gray and affecting aesthetics; Porcelain casting does not have this problem. Combination of internal and external crowns:

--The combination of metal and porcelain is a weak link, and it is often seen that porcelain and metal peel off to expose gray black metal. Porcelain casting is definitely the best combination of porcelain and porcelain because both the inner and outer crowns are made of porcelain.

Wear and tear of the jaw and teeth

--The hardness of porcelain crowns is greater than that of dental enamel, which can cause wear and tear on the teeth. The hardness of Beiyuan porcelain is similar to that of dental enamel, and it wears out synchronously with the teeth.

No metal interference

--Both the inner and outer crowns are made of porcelain, which is perfectly combined with porcelain. Due to the absence of metal components, it not only provides good protection for the patient's health, but also has no impact on possible CT and MRI examinations in the future.

Superior biocompatibility

--The material of Beiyuan Ruimei porcelain has neutral physical properties in the oral cavity. It is very compatible with the biological structure of the human body and has high biocompatibility. It will not stimulate the gums and cause gum inflammation or discoloration.

Scope of application

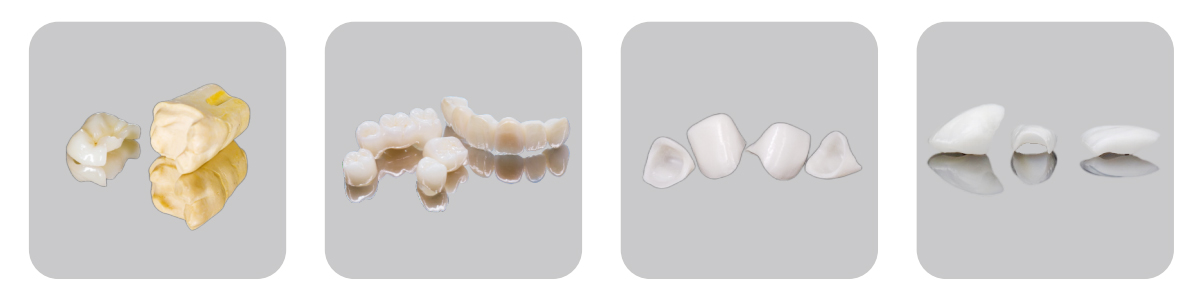

The lithium disilicate glass ceramic block used for Beiyuan all ceramic dentures can be used for denture restoration, such as inlay, veneer, crown, with rich colors that are closer to the patient's natural teeth. With this product, it can be made through normal pressing, with high flexibility and toughness, and the reaction after pressing is negligible, which can make the positioning more accurate. It can be used for making, dyeing, glazing, and according to the needs of a product, different production methods can be used to make dentures that are closer to natural teeth. It has high flexibility, so it is more stable and reliable than other zirconia materials. Even if burned many times, it will not change color and transparency will not change.

HOME

HOME

PRODUCT

PRODUCT

NEWS

NEWS

CONTACT

CONTACT